![]()

The Words of the Herwegh Family

|

|

The Words of the Herwegh Family |

During

True Parents' visit to the IOE plant in 1985. Left to right: Mr.

Hwang; Bob Finamore, regional sales manager; Dr. Martin Porter;

Father; Mother; David Kirpich, sales manager; Heiner Herwegh, general

manager; and Clinton Jones, plant manager.

In June 1978, International Oceanic Enterprises, Inc. of Alabama (IOE) opened its doors. The story of how it began is quite unique.

Earlier that year Master Marine, Inc., which has since become a successful shipbuilding business, bought a shipyard in Bayou La Batre, Alabama. Besides building boats for customers, Master Marine bought its own fishing boats as well. These boats started shrimping and fishing in the Gulf of Mexico with hired captains and crews, from whom the Master Marine brothers could receive professional training.

On one side of their shipyard stood an old shack that had formerly been used as a place where boats unloaded and sold their catches. Some of the brothers thought, "Wouldn't it be great to unload right here and sell our own catch?" And so Dr. Paul Werner, who was responsible for Master Marine at that time, decided to do just that. I he place was fixed up, equipment was bought and installed, a manager was hired, and Master Marine Seafood was born.

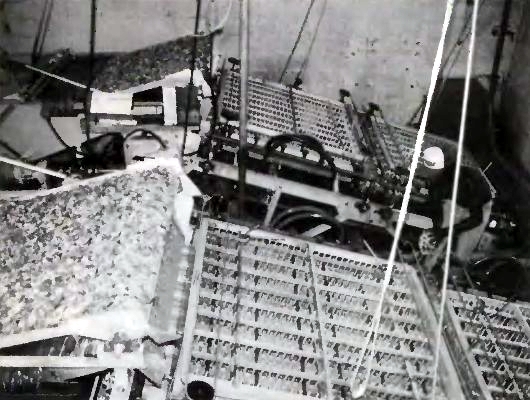

A

bird's-eye view of the facilities at IOE of Alabama.

Meanwhile, across the Bayou, a large seafood plant, including an ice plant and a fuel dock, stood vacant. It had been out of business for many years. The former owner had gone bankrupt, and it came to the attention of International Oceanic Enterprises, Inc. of Virginia that the plant would soon be auctioned off. At that time, Father and "his Moonies" were not too beloved in the area! We were feared as competition by the business community and condemned as kidnappers and brainwashers by the ministers and congregations of the local churches. We were informed that several of the major businesses in Bayou La Batre were united together, determined to stop us from purchasing the plant. If necessary, they intended to drive the price up until we would stop bidding, and then buy the plant for themselves, although none of them were actually interested in owning it. When Father heard about this, he recommended that we not attend the auction, and the plant was sold for a fraction of its real value because nobody really wanted it besides us. A well-known local businessman had made the first bid and no one challenged it. To our surprise, the new owner contacted us immediately following the auction and offered to sell the plant to us for little more than he had bid.

That same day IOE of Virginia became the owner of a new seafood plant, ice plant, and fuel dock, all for about 25 percent of their appraised value! Thus IOE of Alabama came to be. Until this day, the local people believe that the man who bought the plant at the auction was our agent, but in reality we had never met the man before. He himself said that he did not believe that any group should be treated the way we were being treated, and he was unruffled by the public outcry that followed his sale to us.

In the beginning, brothers and sisters did just the manual labor, but within three months we were doing management, processing, and sales. We started to buy not only from the Master Marine fleet, but from other boats and other unloading docks in the area as well, for in spite of rumors, people were attracted by our honesty and our high standards. Now we buy fish and shrimp from Florida, all along the Gulf Coast -- through Alabama, Mississippi, Louisiana, and Texas -- and from the East Coast as well.

A

shrimp peeling machine.

Shrimp come in many different species, sizes, and qualities. Shrimp smaller than 50 per pound with the head on are usually processed through huge machines that remove the head, tail, and shell, leaving only the shrimp meat. These shrimp are then separated by size and packed in five-pound cartons to be frozen. The bigger shrimp can be frozen with the head on or off. They can be individually quick-frozen or separated by size in our grading machines and block- frozen in two- or five-pound packs.

Since 1978 we have been constantly expanding and improving our plant. We have just finished our latest expansion -- a 4,000-square-foot staging and handling area for loading and unloading trucks, plus a major addition to our business-office space.

Over the years IOE of Alabama has grown substantially. We can now grade 2,800 pounds of shrimp an hour, peel 2,200 pounds an hour, and individually quick-freeze 1,800 pounds an hour. Our total blast- freezing capacity is 40,000 pounds a day, and we have a 700,000-pound holding freezer. Last year we processed 7 million pounds of shrimp and over 1 million pounds of fish.

In the busy season, from April to September, we process 19 hours a day and employ 150 regular workers and 100 shrimp headers. Management, sales, and most of the office personnel are now staffed by Unification brothers and sisters.

Since the market changes every day, decisions have to be made and changed continually. Quality has to be monitored at all times. We handle 406 different shrimp items. Profit is generated not only by the difference between buying and selling prices, but also by grading the shrimp exactly according to size and quality and by finding the best type of processing for each grade of shrimp, thus creating the best marketable product. It is absolutely important that sales and processing work together on a day- to-day basis. About a year ago we bought computers to enhance our marketing ability.

Our product is known as one of the best on the American market, outstanding for its quality, taste, and accurate weight and size measurements. Our sales area sweeps from the Midwest to the East Coast, from Florida to Canada. Many restaurants and seafood stores in the surrounding cities are directly supplied every week by our salesmen with six- or ten-wheel trucks. Our tractor trailer and our ten-wheel truck make weekly trips up the East Coast supplying other major cities. We supply our customers not only with shrimp and fish but also with other products such as crab legs, scallops, lobster tails, and frog legs. These we buy from other processors.

We

employ about 100 shrimp headers.

IOE of Alabama has established a good reputation in the seafood industry. Any success, though, is due to our attempt to be centered on God, to follow our True Parents, to unite with Dr. Martin Porter (who succeeded Dr. Werner in 1983 in taking responsibility for all fish-related operations in Bayou La Batre), and to work together as a team to bring success to True Parents. Supporting our True Parents is our main desire, and for that we always try to put differences aside. When we look back, we can see how much Heavenly Father helped us make the right decisions at the right time. Any accomplishment is due to God's blessing on the foundation of our unity.

On December 21, 1986, Father visited us in Bayou La Batre. We were happy to be able to report that our sales were up 40 percent for the year. He predicted that after we reach $50 million in sales per year, we will see IOE grow beyond our greatest dreams.

Presently we are preparing our plant so that it can run 24 hours a day as soon as the season starts in April. We are determined to fulfill Father's ideals and expectations.

Grading

and packing shrimp.

The fishermen who work on the four shrimp boats operated by Master Marine out of Bayou La Batre, Alabama, are definitely unsung heroes, living a life of great sacrifice, hardship, and even danger to realize Father's vision for the ocean. Not many members of the church actually know what they go through. Presently, nine Master Marine brothers plus several non-church members follow a grueling schedule that keeps them out at sea for 14-20 days at a time.

After an eight-hour trip from port out to the shrimping grounds, which stretch along the Gulf of Mexico from Alabama to Texas, the three- to five-man crew on each vessel begins the exhausting process of shrimping. Depending on the size of the boat, two to four large nets are dragged along the ocean bottom, and after four to six hours the nets are hauled up and emptied on the deck. The catch has to be sorted, because most of what is caught in the nets has little or no economic value, often called "by-fish." Some fish, like trout and flounder, are saved, but the majority have to be dumped back into the ocean.

Once the shrimp are sorted out, the crew must laboriously remove the head of each shrimp by hand, because headless shrimp bring a higher market price. The shrimp are then washed and put on ice. This entire operation takes almost three hours; then the nets are dropped for another four- to six-hour run.

While the nets are in the water, most of the brothers can rest while one person keeps watch, but when the nets are brought up the process of sorting, cleaning, and storing begins again. The cycle of work and sleep continues around the clock. Shrimping in all kinds of weather, with irregular sleep that is often interrupted, crews become exhausted after seven or ten days. This is a big hazard, because the deck of a shrimper is a dangerous place if one is not alert and careful. The presence of heavy machinery and complex cables and lines, combined with the constant motion of the vessel, makes even small mistakes potentially fatal.

During storms, the boats usually retreat to anchor in the Mississippi River delta. On such occasions two boats will often tie up together for a bit of "social time" -- to eat together, watch videos, and of course tell fishing stories. After two to three weeks on the water, the fishermen return with their catch to spend a week at home. Most of the Master Marine fishermen now have families, so they tend to stay in port longer than they did several years ago. But readjusting to shore life is not easy. The interrupted pattern of sleep they experience on the boat makes it almost impossible for them to sleep through the night when they are on shore.

Shrimp will fetch the relatively high price of $1.50 to $6.00 a pound, depending on the size, on whether the head has been removed, and on market demand. But the cost of shrimping is also high. A boat must make about $1,000 a day just to meet operating costs. It takes a catch of 2,500 to 3,000 pounds to break even on a trip, 4,000 to 6,000 pounds to make a moderately successful trip, and more than 7,000 pounds to make a really good trip. This season, one Master Marine boat brought in a 20,000- pound catch.

In recent years the shrimping industry has faced hard times. The high price of shrimp has led to over-fishing and a decrease in the number caught. The increasing scarcity of shrimp, combined with higher fuel prices, has forced many boats out of business. The plight of shrimp fishermen today reflects the general decline of the entire fishing industry in America. This situation shows why Father is so desperate to fulfill his vision of the ocean as a storehouse that will feed the world.